Custom Knee Brace in Toronto

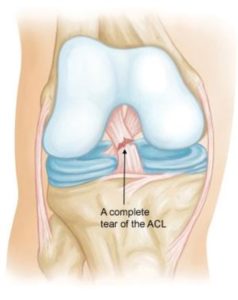

Our knees are part of the musculoskeletal system, and they support most of the body’s weight as we walk, run, exercise, or perform any other physical activities. The bones at the knee joint are connected by several ligaments, including the anterior cruciate (ACL), posterior cruciate (PCL), medial collateral (MCL), and lateral collateral (LCL).

Among athletes, knee injuries that cause ligament tears are the most common injuries to the musculoskeletal system. The most affected ligament is the ACL because it’s located at the front part of the knee.

When a ligament tears, it becomes uncomfortable to walk or perform more demanding physical activities. If proper treatment and precautions are not taken, further damage will occur to the affected ligament.

A custom knee brace, in combination with other treatment methods, such as physical therapy, and at times reconstructive surgery, is the standard method of ensuring a quick recovery of the affected ligament, while preventing further damage to it.

Quick links to the contents:

Custom Knee Brace for ACL and PCL Tears

Arthritis Unloading Custom Knee Brace

How Do I Get a Custom Knee Brace?

Why Choose Us for Your Custom Knee Brace?

Not Sure If You Require a Custom Knee Brace?

What Is A Custom Knee Brace?

A custom knee brace is a medical device designed to support the knee joints when suffering from an injury or other underlying conditions, including arthritis. It is designed to perfectly fit an individual’s needs to provide support, prevent progression of a current injury during rehab, and to prevent re-injury after recovery.

At Push Pounds Sports Medicine, we believe that “one size fits all” never really fits. Every individual has a unique musculoskeletal system, and therefore requires an ideal knee brace for their joints to facilitate proper healing, protection, and support. This is why we strive to provide the best custom knee braces in Toronto.

Custom Knee Brace for ACL and PCL Tears

When your ACL or PCL tears, the excruciating pain makes it impossible to perform physical activities. Without proper care and treatment, more damage can occur to the affected ligament.

A custom knee brace for ligament tears stabilizes the affected knee to prevent injury progression and allow the damaged ligament to heal. If your ligament suffered a partial tear, the custom knee brace prevents a complete tear.

A custom knee brace allows a certain level of movement during rehab workouts or other physical activities. It does this while helping to protect the injured ligament.

For athletes or individuals with an old ligament injury, custom knee braces support the affected knee and prevent stress on previously injured ligaments. This allows you to move around and perform physical activities reducing the risk of re-injury.

If you have a ligament tear, an old knee injury, or you’re looking to prevent injuries to your knee, Push Pounds Sports Medicine offers high-quality custom knee braces in Toronto. We also provide a comprehensive physiotherapy treatment plan to aid in your recovery.

Arthritis Unloading Custom Knee Brace

Osteoarthritis is an inflammatory disease that affects the joints, in particular the knee joints. The inflammation causes pain and discomfort, and limits your overall movement.

Active individuals who have a history of knee injuries, including ACL & PCL tears, cartilage contusions, and other knee-related injuries, are at a higher risk of getting arthritis. At Push Pounds Sports Medicine, we have helped many athletes and other individuals who have arthritis of the knee due to previous injuries or other factors.

Push Pounds Sports Medicine, we utilize customized arthritis knee braces in conjunction with a personalized rehabilitation treatment plan to relieve pain and discomfort. The custom arthritis knee braces that we offer, work by shifting weight and stress away from the affected area of the joint, making it comfortable to move around and perform physical activities.

How Do I Get a Custom Knee Brace?

At Push Pounds Sports Medicine, acquiring a high-quality custom knee brace involves a few simple steps.

Assessment

During your first session, our specialist will examine your knee and the rest of the musculoskeletal system. This thorough examination enables our specialists to assess the condition of your affected knee and the musculoskeletal system as a whole.

Fitting

After a detailed assessment of your affected knee, the specialist can determine the ideal knee brace for your specific condition. A fitting is then done, and detailed descriptions of your medical condition and the custom knee brace required are sent to our trusted manufacturer. The necessary arrangements to cover the cost of knee brace are also made with your insurance provider. To learn more about the cost of our custom knee braces, kindly contact us.

Pick Up and Follow Up Sessions

The turnaround time for our custom knee brace is short. Once we receive your knee brace from our manufacturer, we schedule a pickup session. During this session, our orthotics specialist puts the knee brace on the affected knee and checks its fitting and functionality. If it fits as required, the specialist shows you how to wear and remove the brace, and instructs you on when to use it.

Why Choose Us for Your Custom Knee Brace?

Push Pounds Sports Medicine is one of the biggest and best rehab and performance centers for athletes in Toronto. We offer a personalized healthcare system for treatment, rehabilitation, and performance enhancement for all our clients.

We have a highly qualified team of specialists ready to offer their expertise to expedite your recovery, and ensure that you’re performing at your best. When it comes to knee injuries or conditions, we have orthopedic surgeons, chiropractors, physiotherapists, and other experienced personnel ready to work with you.

We are located in the heart of Toronto, and our facility has everything you’ll require during your recovery. Contact us today and benefit from the top sports medicine center in Toronto.

Not Sure If You Require a Custom Knee Brace?

If you have a knee injury or pain, but you’re not sure if a custom knee brace could benefit, get a referral to one of our orthopedic surgeons. They’ll examine your knee and review your scans to help you make a well-informed decision based on your knee’s condition.

Get in touch with us to learn more about our custom knee braces and how they can benefit your knee joint and general health.